Prof. Glenn H. Chapman: SFU Eng. Science

Research Equipment

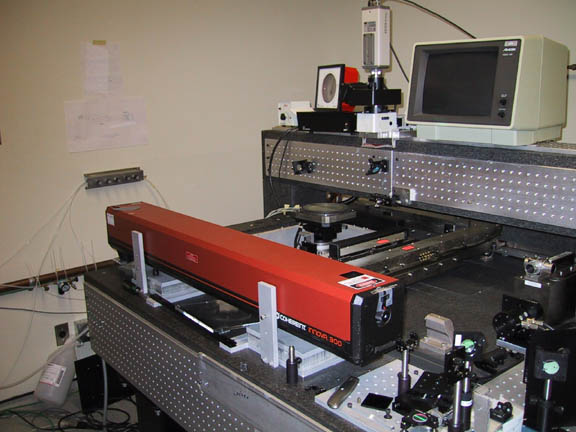

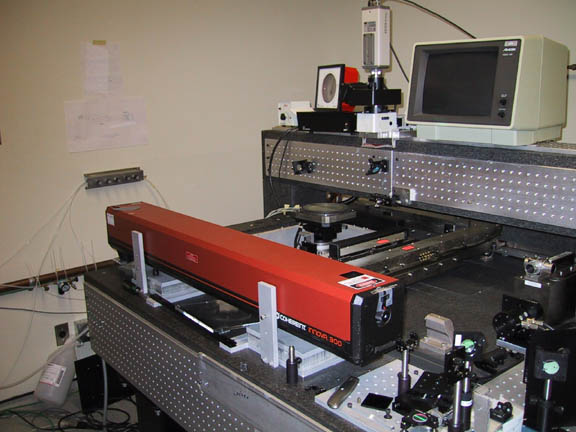

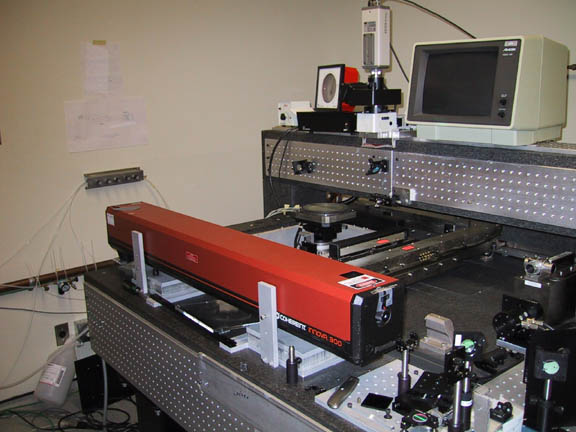

Laser Table equipment consists of a focused 5 watt argon ion laser beam

(488/514 nm wavelength) with spot sizes down to 1 micron full width half

maximum. An electro-optic shutter controls the beam pulse duration from

single 2 microsecond pulse through to continuous exposure and multiple

pulses. IC's are positioned below the beam using a laser interferometry

controlled XY table with position accuracy of 0.1 micrometers over a 25x25

cm area. The table can move to locations and stabilize in less than 0.1

sec for distances less than 1 mm, and about 1 second for the full 25 cm.

A TV camera image of the laser position area is displayed in the control

system computer using a real time frame grabber on the TV microscope image.

Digitally stored images can be taken of the cut points to verify the location

of operations. IC's can be worked on in any of the following formats: chips

or wafers, 24 or 40 pin DIPS, 64 pin-grid arrays. The combined laser, shutter

and positioning system operates under a integrated MSWindows control system

developed here at SFU. The system allows automatic moving to position,

adjustment of the pulse parameters (duration, number of pulses, shape etc)

and firing of the laser pulse. Scripts of control commands enable the table

to move through a sequence of operations without needing any user input.

Laser Table equipment consists of a focused 5 watt argon ion laser beam

(488/514 nm wavelength) with spot sizes down to 1 micron full width half

maximum. An electro-optic shutter controls the beam pulse duration from

single 2 microsecond pulse through to continuous exposure and multiple

pulses. IC's are positioned below the beam using a laser interferometry

controlled XY table with position accuracy of 0.1 micrometers over a 25x25

cm area. The table can move to locations and stabilize in less than 0.1

sec for distances less than 1 mm, and about 1 second for the full 25 cm.

A TV camera image of the laser position area is displayed in the control

system computer using a real time frame grabber on the TV microscope image.

Digitally stored images can be taken of the cut points to verify the location

of operations. IC's can be worked on in any of the following formats: chips

or wafers, 24 or 40 pin DIPS, 64 pin-grid arrays. The combined laser, shutter

and positioning system operates under a integrated MSWindows control system

developed here at SFU. The system allows automatic moving to position,

adjustment of the pulse parameters (duration, number of pulses, shape etc)

and firing of the laser pulse. Scripts of control commands enable the table

to move through a sequence of operations without needing any user input.

The laser table is being converted in a UV Laser micromachining system

by the addition of a Nd:Yag laser which produces high power light pulses

at the IR (1064 nm), Green (533 nm), UV (266 nm) and Vacuum UV (213 nm)

wavelengths. This will enable photoablative cutting plastic material for

biomedical applicaitons.

Microfabriction and micromachining research work at SFU's microfabriction

laboratory including oxidation/doping furnaces, film RF sputter deposition

system, photolithography, wet etching stations and inspection/measurement

equipment.

Several Pentium I/II/III class PC's for personal use of my Graduates

students. Design work using SFU's VLSI Design facility with 2 Spark 10,

2 Spark 20 and one IPX file server. IC design with Cadence and Kic computer

aided design tools. Analysis with Hspice circuit simulation, Ansys fine

element program and Ssupreme4 processing simulation. Access to Canadian

Microelectronic Corp.'s 3 micron, 1.2 micron, 0.8 micron and 0.5 mircon

mulitproject wafer design submissions.

Funding Support

Funding for this research comes from NSERC Operating grants, B.C. Advanced

Systems Institute Senior Fellowship, a major grant from the Canadian Foundation

for Innovation, BC Knowledge Fund, and Centre for System Studies Strategic

Studies grants, plus industrial research grants.

Back to Prof. Glenn Chapman Home

ENSC Faculty or Engineering

Science People or Engineering Science Home Page

Page maintained by: Glenn Chapman

Last updated Mar. 10, 2001